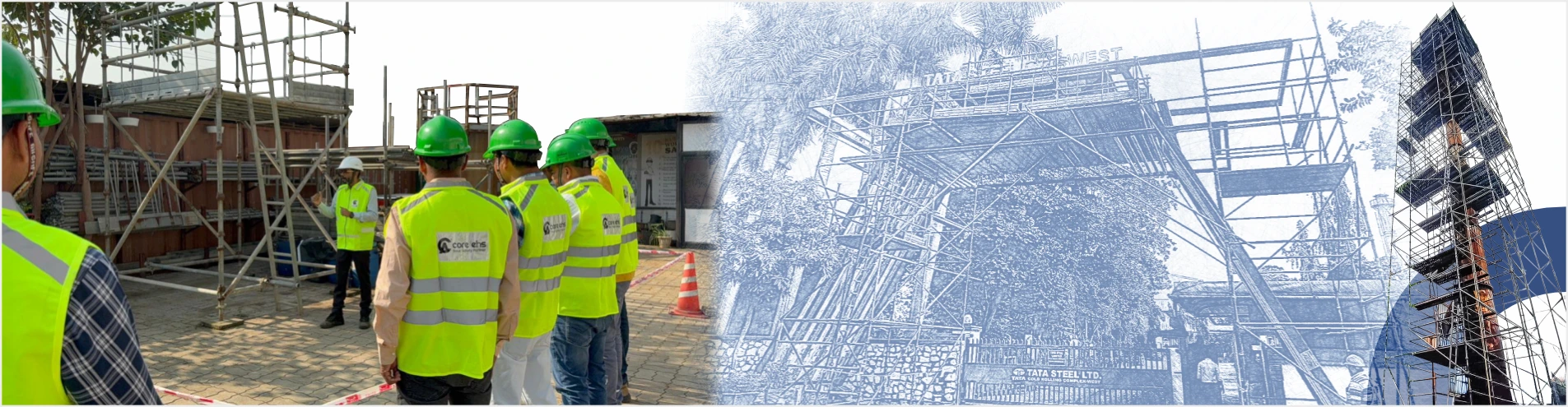

Why Choose Our Scaffolding Services

About Our Scaffolding Expertise & Capabilities

Scaffolding has been crucial for construction, repair, and maintenance of multi-storey buildings, providing safe and temporary access at heights. Its primary components are tubes and boards, with various systems like tube-and-clamp, fabricated frames, and modular designs offering unique benefits.

Founded in 2007 in Surat, India, ASK-EHS Engineering & Consultants Pvt. Ltd. (Now CORE EHS) is a leader in the scaffolding industry, specializing in training, erection, inspection,hire, and sale of system scaffolding. With over 500 skilled scaffolders and inspectors, we ensure all scaffolding perations are safe and compliant with health and safety requirements, continuously improving safety systems and maintaining an impeccable safety record.

+91 72929 29357

+91 72929 29357  info@coreehs.com

info@coreehs.com